Laura Murphy, a PhD candidate at BiOrbic explores how reusing large volumes of liquid waste produced by drug manufacturing, specifically waste made by yeast, can lead to more sustainable drug production.

“Do you want to get in after me?” – Reusing microbial ‘bathwater’ for sustainable drug production.

Solving the global warming crisis often seems like an impossible task. Plastic waste, carbon emissions, wastewater production, habitat loss - the list of challenges is almost endless. Thankfully, a lot of scientific research goes into tackling these problems, and many successes have been found to date. This progress is in part thanks to companies like BiOrbic, who help fund my research. Based on UCD campus, BiOrbic is a Science Foundation Ireland funded research centre that focus their projects on those related to improving processes and promoting sustainability and the circular bioeconomy through research and innovation.

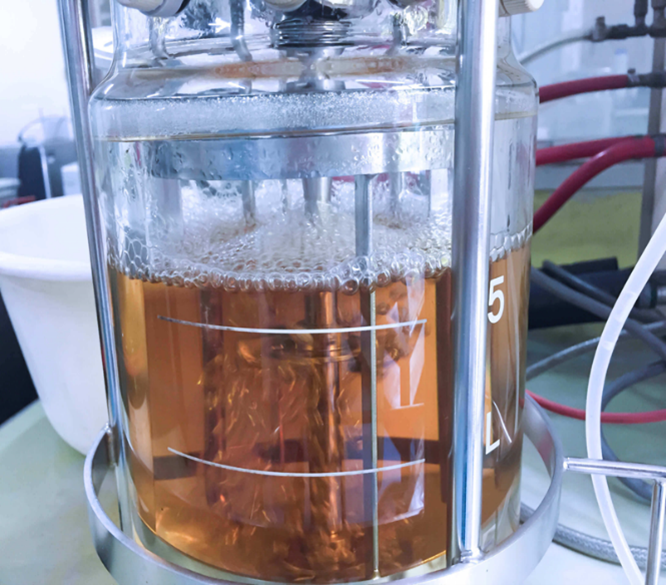

My PhD research aims to make use of the large volumes of liquid waste produced by drug manufacturing, specifically waste made by yeast. Yeast is an incredibly important microorganism, responsible for producing half the global supply of the commonly used drug insulin, used to treat diabetes. Every day the world generates millions of litres of liquid waste from these drug manufacturing processes and nothing useful is done with it. It is either chemically treated and inactivated, or part of it is incinerated. This is hugely wasteful and environmentally damaging, especially when considering the amount of water used in the process, the harsh treatments applied, and the chemicals released when waste is burned. This waste begins the drug manufacturing process as a complex high value material – once which contains the perfect balance of nutrients to sustain and support the growth of microorganisms. So we asked ourselves, what value remains in this liquid once it is considered ‘waste’. Is there anything else we can do with it to not only be more economical but also avoid the damage that its disposal does to the planet? Below is an image of what this liquid waste looks like, to give an idea of what we were working with:

So began our research quest. We had identified our purpose and primary question, and the next task was to design an experiment that would help us answer it. My research group primarily works with bacteria, engineering them to make a specific protein that glows a purple/cherry colour. Therefore, a logical question that followed was “could we grow our bacteria in yeast waste whilst still producing our desired protein?”. Knowing that microorganisms are very particular about the conditions they want to grow in, we had to do some specific investigations into what was in the waste. Using highly sensitive technologies, we were able to identify the main energy sources and nutrients the yeast had used up while they were growing (essentially, what was now missing from the liquid). We then did the same thing with the bacteria, discovering the things they liked the most while they were growing. Things they absolutely require for cell division and protein production.

If you were to think of our conical flasks like a spa or resort, then the yeast had left it in a bad state. The pools were now green and dirty, with sodden towels and empty soap dispensers everywhere – doesn’t sound very zen does it? From our previous study, we knew the bacteria wouldn’t be happy there. The spa would need a bit of ‘renovation’ through adding the specific nutrients identified - a bit of magnesium here and some amino acids there. Amino acids in particular would be essential as these are the building blocks of life, and are really critical for making proteins.

With the spa now renovated, did our bacteria like it? In short, yes, they certainly seemed happy! Firstly, they were growing well. In fact, the bacteria in our renovated spa were growing at a very similar rate compared to those grown in the standard “LB media” (or the ‘Four Seasons’ of bacterial spas). Good growth rates were a really nice indication that our bacteria were nice and happy in their environment, but the big test would be how well they could produce our purple protein. In theory, this protein could be any protein that bacteria produce in industry, from anti-cancer drugs to diagnostics for drug discovery. So if we could produce large amounts of these valuable products using a waste source, that would be worth investigating.

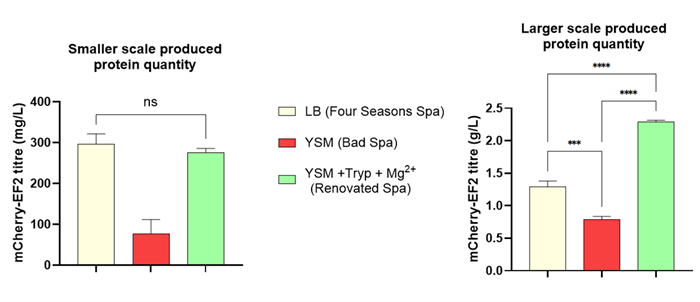

In smaller volumes (to start with), we measured the amount of product we were getting in our bad spa (nothing added, just waste), our renovated spa (waste + the two additives), and our comparison standard LB media (our Four Seasons). The initial results were exciting. The bacteria had managed to produce a statistically equal amount of our protein both in the renovated spa and in the standard LB media. Encouraged by this, we decided to expand our ‘spa’ – increasing the volume of waste we were growing our bacteria in to better represent the large volumes that are used in industrial processes. The scale-up was just as interesting. In this larger volume, our renovated spa performed the best by a large distance, with more volumes of the protein being produced there than in the standard LB media. Below are figures showing these results, from both the smaller scale experiment, and the larger experiment:

So what does this work mean? I hope we have illustrated that there is a huge opportunity for researchers and those in industry to be making use of what is currently considered “waste”. Consider the global impact if we were able to take the waste produced from making drugs like insulin and use it in secondary bacterial processes. Following some simple 'renovation’ we can supply potentially lifesaving therapeutics, whilst also avoiding environmental damage. The potential of maximising the untapped value of waste, demonstrated by this research, should not be understated. There is still a long way to go in terms of the large scale implementation of improvements like this, but it is certainly a step in the right direction towards a more sustainable future.

Essay first published 1 July 2024.

About the author

Laura Murphy attended UCD for her undergraduate degree in Pharmacology, and her Masters in Biotherapeutics. She is now in her third year of her PhD in the O'Connell lab in the UCD Conway Institute. Her work centres around sustainability in bioprocesses involving yeast, seeking to find value in what is considered waste products. Her PhD work is funded by BiOrbic and SFI.

Laura Murphy attended UCD for her undergraduate degree in Pharmacology, and her Masters in Biotherapeutics. She is now in her third year of her PhD in the O'Connell lab in the UCD Conway Institute. Her work centres around sustainability in bioprocesses involving yeast, seeking to find value in what is considered waste products. Her PhD work is funded by BiOrbic and SFI.

About the series

The A-Z of Environmental, Climate and Sustainability Research is a new series of short essays by UCD postdoctoral and postgraduate researchers, technical and research support staff, about their work. The series is developed and curated by the Earth Institute Associate Member Committee led by Hannah Gould, a PhD student at BiOrbic and the UCD School of Architecture, Planning and Environmental Policy, and Earth Institute Communications and Engagement Officer Liz Bruton. If you'd like to submit a piece for the series do get in touch!

Find out more about the Anthropocene with Nick Scroxton, Bees with Katherine Burns, Cannabis with Caroline Dowling, Degrowth with Ciarán O'Brien, Education with Georgina Fagan, Finance with Shane McGuinness, Gaia with Federico Cerrone, Hydrometry with Kate de Smeth, Innovation with Hannah Gould, Justice with Lauren Minion, Kelp with Priya Pollard, Landscape part 1 with Tomas Buitendijk, Landscape part 2 with Amy Strecker and Amanda Byer, Reusing microbial ‘bathwater’ for sustainable drug production with Laura Murphy, and Mammals with Virginia Morera-Pujol in our latest essays.

Further reading

Murphy, L.; Lynch, C.D.; O’Connell, D.J. Valorisation of Spent Yeast Fermentation Media through Compositional-Analysis-Directed Supplementation. Appl. Microbiol. 2024, 4, 959-971. https://doi.org/10.3390/applmicrobiol4020065

Lynch CD, O’Connell DJ (2022) Conversion of mammalian cell culture media waste to microbial fermentation feed efficiently supports production of recombinant protein by Escherichia coli. PLOS ONE 17(5): e0266921. https://doi.org/10.1371/journal.pone.0266921

https://atriainnovation.com/en/blog/waste-valorization/

https://www.weforum.org/agenda/2020/10/circular-bioeconomy-nature-reset/