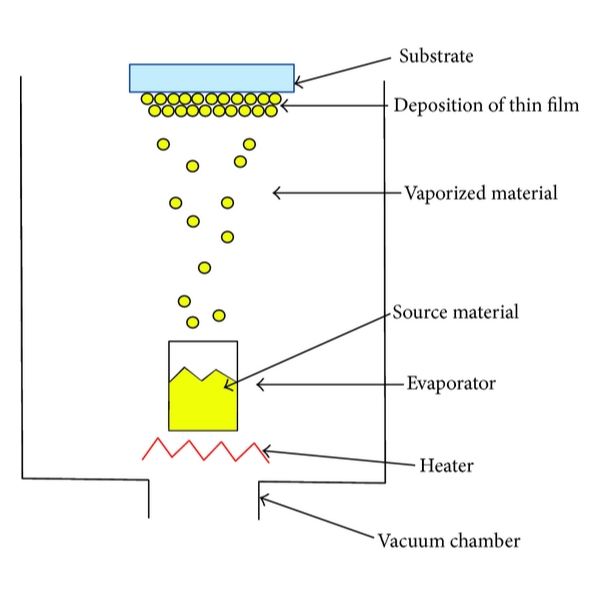

PVD machine

The PVD machine is an essential piece of equipment in any materials' laboratory. It allows the coating of a wide range of materials, from metals, like silver and gold, to ceramics, like silicon dioxide. The PVD machine is capable of depositing these materials in very thin layers, on the order of nanometres. The machine uses a high current source to heat the material to be deposited to its evaporation temperature where it leaves the bulk material and coats the sample. The machine is equipped with water cooled electrodes and has an effective coating area of six standard microscope slides. Currently, it is capable of depositing one material at a time, but a third electrode is being built to allow three different materials to be deposited without breaking the vacuum.

Nanosurf NaniteAFM

"The surface morphology is an important property for many high-tech surfaces with features that can go down to a few nanometers and surface roughness below the nanometer. With AFM such features can be readily analysed under ambient conditions. Most AFMs are limited in the type and size of samples they can handle. The NaniteAFM by Nanosurf is the market leading solution for AFM integration with least restriction to the sample dimensions. The NaniteAFM has a tip-scanner, two inspection video cameras and an on-board approach motor in an exceptionally small footprint. It contains everything needed to operate independently, paving the way for easy integration: All you need is 300 cm3 in space and a stable docking site to mount the AFM."

Oxford Instruments Cypher AFM

"The Cypher S was the first commercially available fast-scanning AFM, and the Cypher family AFMs remain the only full-featured fast-scanning AFMs that are compatible with a complete range of modes and accessories. Cypher AFMs have also earned a reputation for easily achieving higher resolution than other AFMs."

TPT Wire Bonder

"The HB16 series bench top size wire bonder is easy to use and ideal for laboratories, pilot production runs and small scale production lines, configurable with a single bondhead for ball and wedge bonding. An intuitive user interface provides the user with access to all of the bond parameters and bonding recipes stored on the machine. The HB16 series also benefits from a motorised Y and Z axis giving a greater control over the looping parameters, allowing the user to create consistent and repeatable wire bonds with ease."